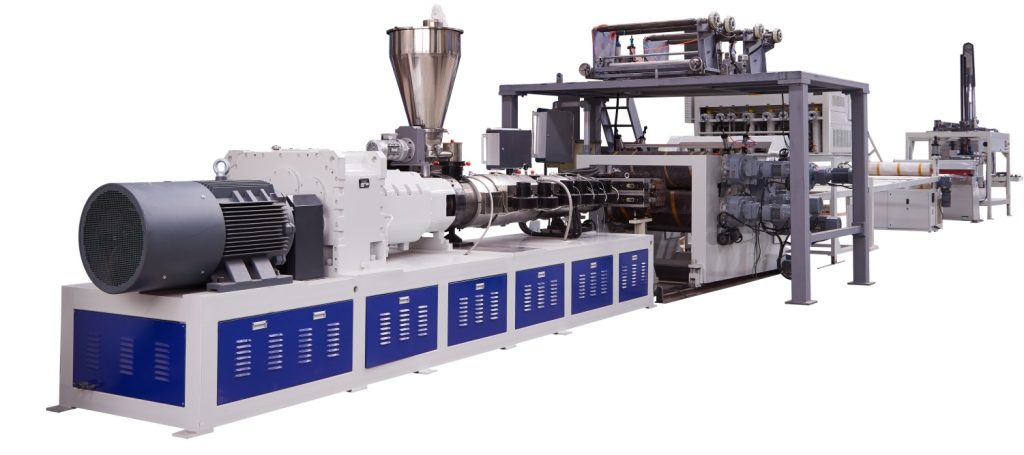

Marble sheet extruder

An extruder is a mechanical machinery that turns raw materials into a final product with the desired shape and dimensions. In the extrusion process, raw materials, which usually include polymers, additives, and pigments, enter the machine and after melting and mixing, pass through special molds to form marble sheets.

The extruder machine for producing marble sheets is one of the advanced tools in the construction and decorative materials production industry. This machine has become very popular among manufacturers due to its ability to produce marble sheets with high quality and lower cost.