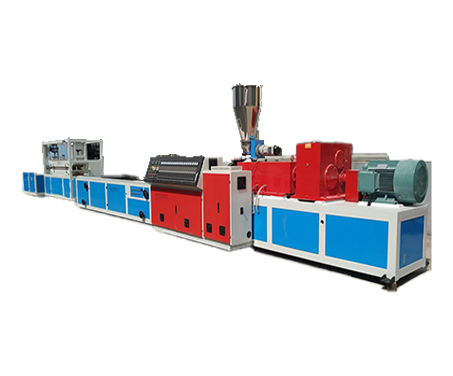

PVC extruder

A PVC extruder is an industrial machine designed to convert PVC raw materials into final products using heat and pressure. This machine melts PVC materials and makes them into various products such as pipes, profiles, sheets and decorative pieces through different molds. PVC extruder machines with the ability to adjust different parameters provide the possibility of producing quality and uniform products.