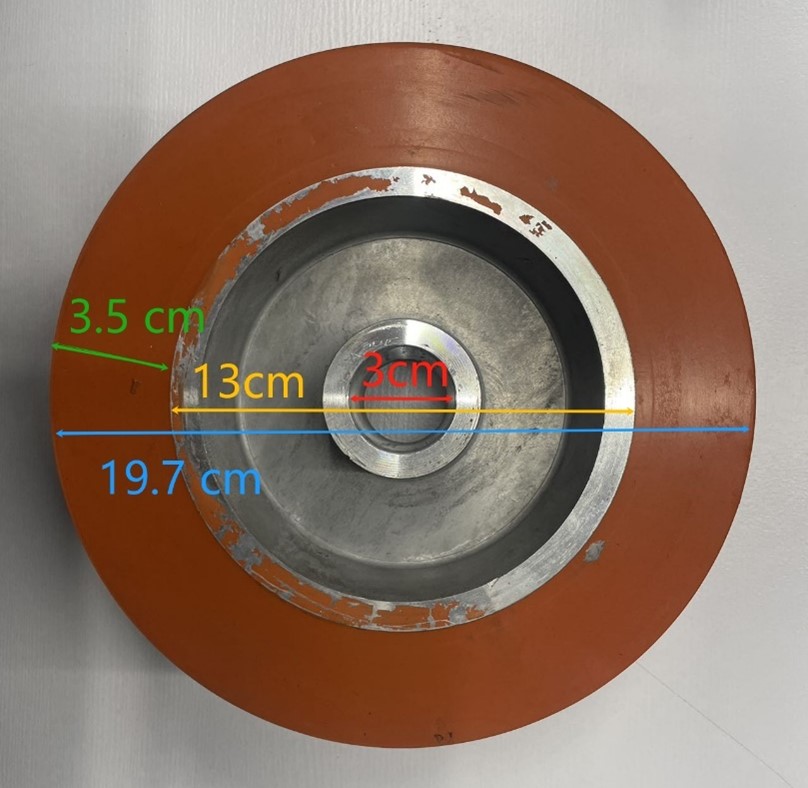

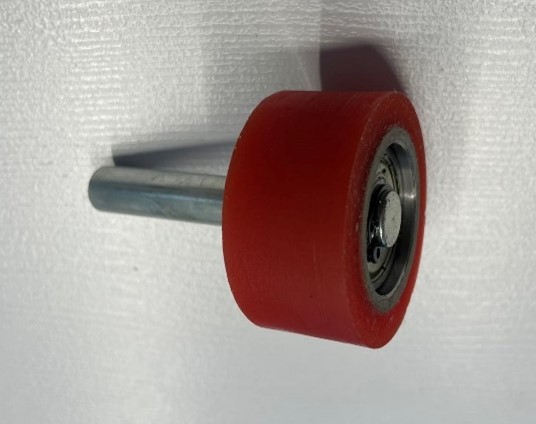

Hand-cut silicon

The manual silicon grinding machinery is in its simplest form, it has a work table, a speed adjustment motor, a grinding blade, and a part called a vacuum cleaner to collect the cut silicon chips.

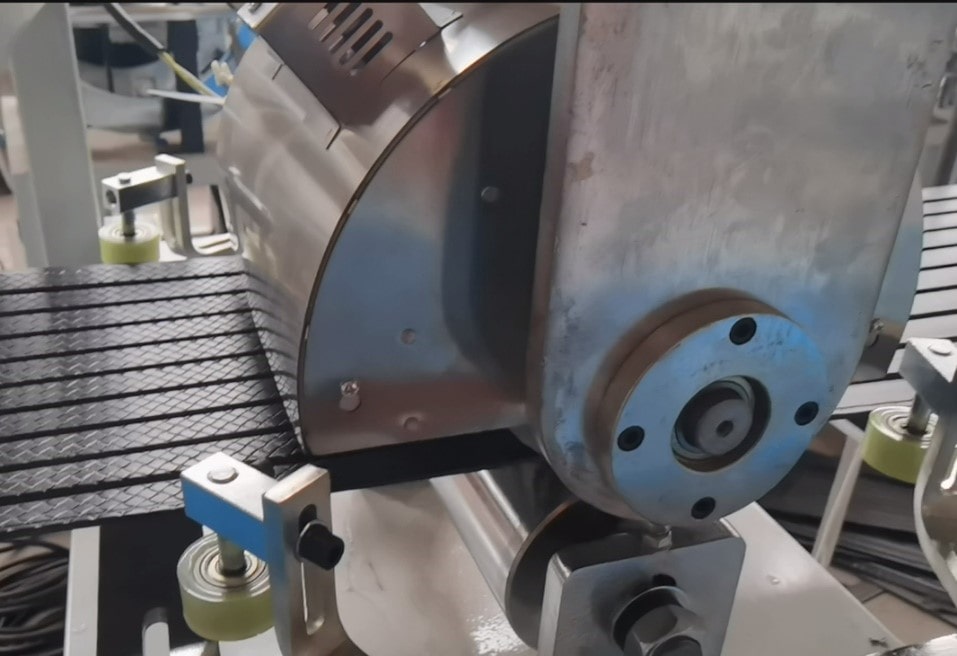

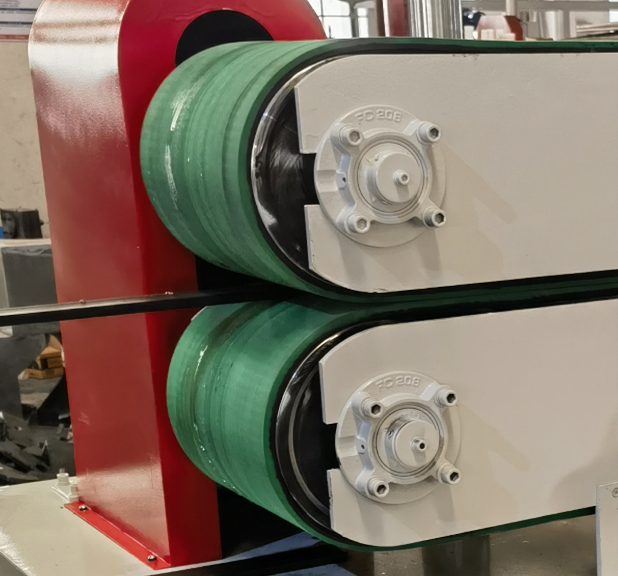

Automatic silicon lathe

The automatic machinery includes the main body in which the motor of the machine is placed, the part of the control panel where all commands are given to the machinery through this part, the part where the thermal silicones are placed inside the chamber, the cutting blade and the chamber door, which increases the safety of the work.